By: Nina Leona

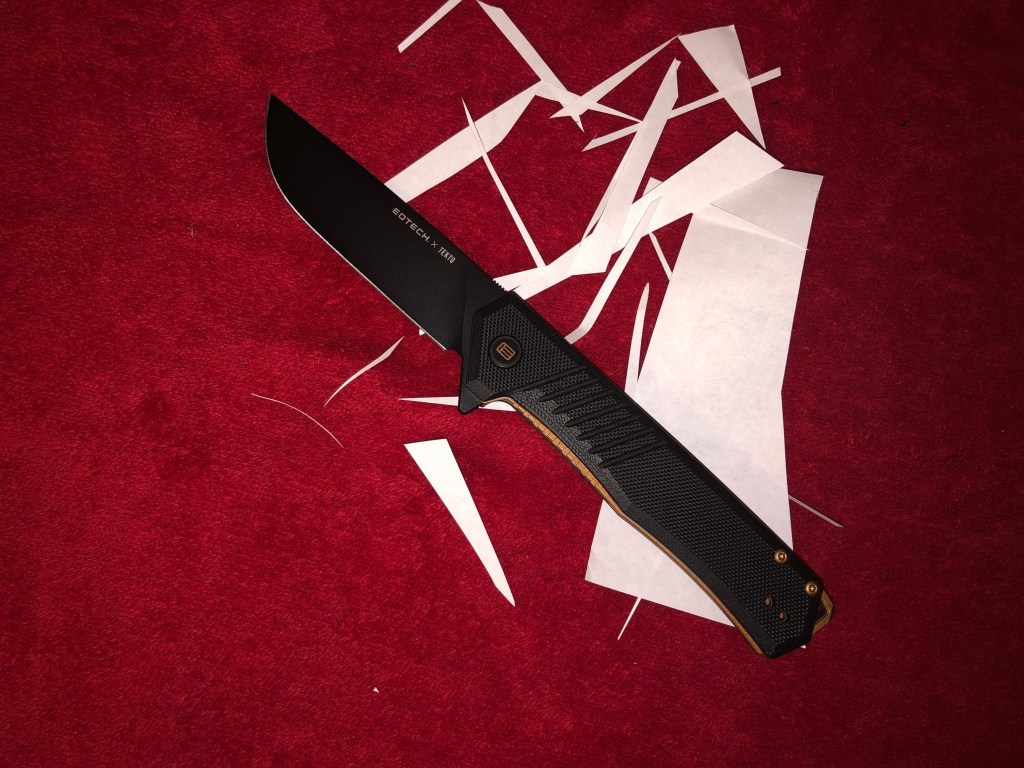

The F1 Alpha is Tekto’s answer to professionals who can’t afford second chances — military operators, first responders, and anyone who needs a knife that will perform under pressure. Compact, light, and brutally efficient, the F1 Alpha blends battle-ready materials with refined mechanics: a 3.10″ titanium-coated D2 blade, an ergonomic G10 + carbon-fiber handle, and ceramic ball bearings for instant, repeatable deployment. It’s a tool engineered to work — reliably, every time.

Design & feel

The F1 Alpha was designed around two priorities: speed and control. At just 3.3 oz (86 g) it’s easy to carry all day without fatigue, yet the low profile and aggressive texturing on the G10 + carbon fiber scales deliver an excellent grip the moment you pick it up. Bronze accents add a tactical, no-nonsense aesthetic while the modified straight-back blade gives a generous cutting edge and a tip geometry that’s both robust and precise.

Key specifications

Handle Material: G10 & Carbon Fiber

Blade Material: Titanium-Coated D2 Steel

Blade Hardness: 58–60 HRC

Blade Style: Modified Straight Back

Locking Mechanism: Liner Lock (reliable, familiar)

Measurements:

• Blade Length: 3.10” (80 mm)

• Handle Length: 4.50” (115 mm)

• Open Length: 7.78” (197 mm)

• Handle Width: 0.45” (11.4 mm)

• Weight: 3.3 oz (86 g)

Materials that matter

• D2 steel (titanium-coated): D2 is a high-carbon, high-chromium tool steel known for exceptional edge retention and wear resistance. The titanium coating adds corrosion resistance, reduces reflectivity, and protects the geometry of the edge during harder tasks. At 58–60 HRC the F1 Alpha balances toughness with long-lasting sharpness.

• G10 + Carbon Fiber handle: Combines strength, lightness, and tactile traction so the knife stays secure in every grip — from fine-motor tasks to heavy pressure work.

Fast & consistent deployment

The Alpha uses ceramic ball bearing technology in its pivot, promoting lightning-quick, smooth blade rotation. Paired with an ergonomically positioned flipper or thumb stud, it lets you open the blade with minimal effort and maximal control — crucial when speed and reliability count.

Locking and carry

A tried-and-true liner lock secures the blade in the open position with confidence and simplicity. The F1 Alpha’s slim profile and light weight make it an unobtrusive EDC or a compact mission tool, while the strong pocket clip ensures secure tip-up carry and easy access.

Field test expectations — cutting trials

Below are practical, real-world expectations for the F1 Alpha across common enthusiast tests. These reflect the knife’s materials, geometry, and intended use.

• Hair shaving test: Achievable with a fine factory edge or a quick stropping. The modified straight-back grind gives a keen cutting line; a finished edge will usually shave arm hair cleanly.

• Rope cut test: Performs very well. The full flat grind and D2 edge retention make slicing through nylon or utility rope efficient and repeatable. Expect minimal sawing and clean severing.

• Denim cutting test: Effortless. Multiple fabric layers — including heavy denim — are handled cleanly thanks to the blade’s edge geometry and the momentum provided by a compact, controllable handle.

• Cardboard cutting test: Excellent for box duty. The combination of flat grind and D2’s durability makes short, sustained cuts through corrugated cardboard effective with slower dulling than softer steels.

• Hardened plastic (white straw) shaving test: Capable. Thin hardened plastics and tubing will slice and can be shaved with a sharp edge; the titanium coating protects the edge during this kind of synthetic work.

• Paper cutting test: Trivial. Clean, snag-free paper slices are a baseline — the F1 Alpha passes with ease.

• Wood shaving test (particle board / thin shavings): Good for light paring and feathering. The blade can produce thin shavings and do small-scale wood prep; it’s not a chisel or dedicated woodworking blade, but it handles controlled paring tasks confidently.

• Aluminum can cutting test: Possible but not routine. The Alpha will puncture and slice thin aluminum if needed; however, repeated metal-on-metal contact may accelerate edge wear or risk minor chipping, so reserve this for emergencies.

Summary of test performance: the F1 Alpha is optimized for quick, controlled cutting tasks where edge retention and reliability matter. D2’s hardness combined with a full flat grind results in a blade that stays sharp through daily chores and tactical use, while the titanium coating gives an added layer of defense.

Handling under pressure

In high-stress situations, ergonomics and deployment are everything. The F1 Alpha’s handle contours, textured surfaces, and balanced weight create a secure, repeatable platform for both precision work and heavy hand pressure. The ceramic-ball pivot keeps deployment smooth even after dirt and debris exposure, and the liner lock offers a familiar, robust lockup when you need it.

Who should carry the F1 Alpha?

• Military and law-enforcement personnel who need a dependable backup blade.

• EMTs and rescue professionals who require quick deployment and precise cutting.

• Outdoor enthusiasts and tradespeople who favor a compact, rugged folder that won’t weigh them down.

• Everyday carriers who want a tactical, mission-capable knife that’s also comfortable for daily tasks.

Final thoughts

Compact, fast, and tough, the Tekto F1 Alpha distills key tactical features into a light, highly usable package. With a hardened D2 core, titanium protection, ceramic-ball deployment, and an ergonomically superior G10/carbon handle, it’s a knife built to be trusted. Whether you’re on duty, on the trail, or opening boxes at home, the F1 Alpha is designed to perform — without drama, without compromise.

For official product details and availability, visit: https://www.tektoknives.com/